9. Care, Maintenance & Correcting Problems

Looking after an instrument will reduce the need for professional maintenance, although this is sometimes unavoidable. The most common problem after the playing-in period is a recorder becoming increasingly clogged or muffled in sound, due to the constant exposure to moisture. This makes the wood alternately expand and contract by tiny amounts, causing the block (inside the mouthpiece) to swell and sometimes reduce the efficiency of the instrument. Clogging is encountered more commonly with denser (darker) woods, and can usually be reduced with a few drops of anticondensant or a special detergent. The recorder should be held upside-down and the solution squeezed into the windway via the front window or labium, then blown through to clear any excess.

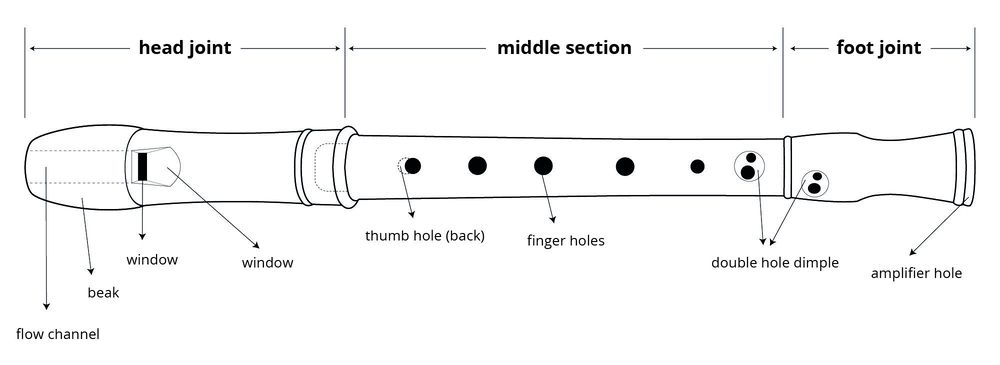

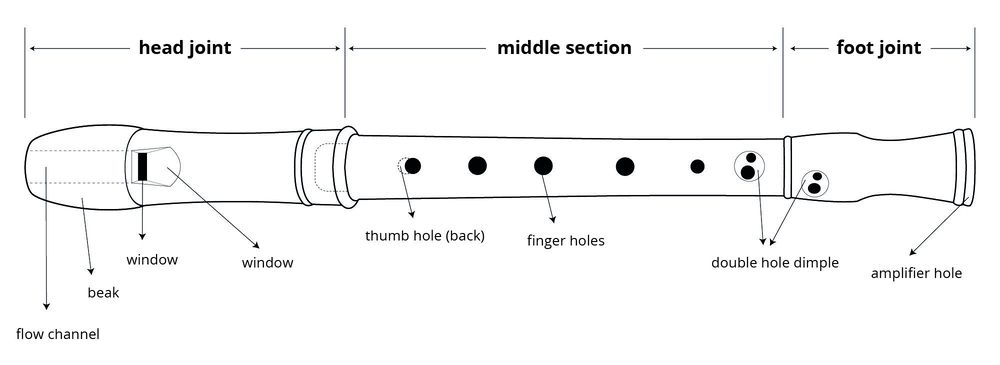

Recorder

Some maintenance and ongoing care is the responsibility of the owner. Keeping the cork (or sometimes thread) joints greased will ensure the recorder fits together and comes apart easily small pots of cork grease are usually included with new instruments, but Vaseline works just as well. Broken cork or unravelled thread is not difficult to fix, and should not be allowed to deteriorate. On large recorders, springs, key mechanisms and pads will occasionally require attention.Revoicing, carried out by a professional, may also sometimes be necessary. The process involves removing and shaving down or reshaping the block, before re-inserting it, and clearing out any deposits at the same time. The recorder will then be re-checked for tuning before its return. Some makers will revoice at a reduced rate or even free of charge within the first year of purchase, particularly with more expensive models, as a certain amount of change is expected while the instrument is played in. Tuning inaccuracies can also be corrected professionally by carefully enlarging the fingerholes, or dripping and moulding wax to make them smaller as appropriate.

Regular oiling of the inside bore is essential. Depending on the wood and the frequency of playing, attention with almond oil roughly once a month will keep it in good condition. This can be a messy process and should preferably be carried out over a cloth or newspaper, with a dedicated recorder mop reserved specifically for the purpose, i.e. not the same mop used to remove condensation caused by playing. The aim is to prevent the inside of the recorder from becoming too dry and therefore prone to cracks - only a thin film of oil should be applied, and it should not be allowed to collect in the fingerholes. The labium surface should also be lightly oiled with a paintbrush, and any excess oil wiped away with a cloth. Its vital that the recorder is absolutely dry before oiling - it should not have been played for one to two days beforehand. After oiling, do not play it for at least another day, leaving it outside the case to allow the oil to seep into the wood. Almond oil is often available from larger chemist stores.

Recorder (almond) oil

Anticondensant

After several years of playing, the thumbhole may begin to wear away. The initial stages of this type of damage are not harmful to the recorder and can be mended, but extensive wear will make the higher notes more difficult to reach and control. A professional can fix this using a process known as thumb-bushing, where the back hole will be gouged out to a larger diameter in order to insert a plastic ring, thereby recreating a thumbhole of the original size.